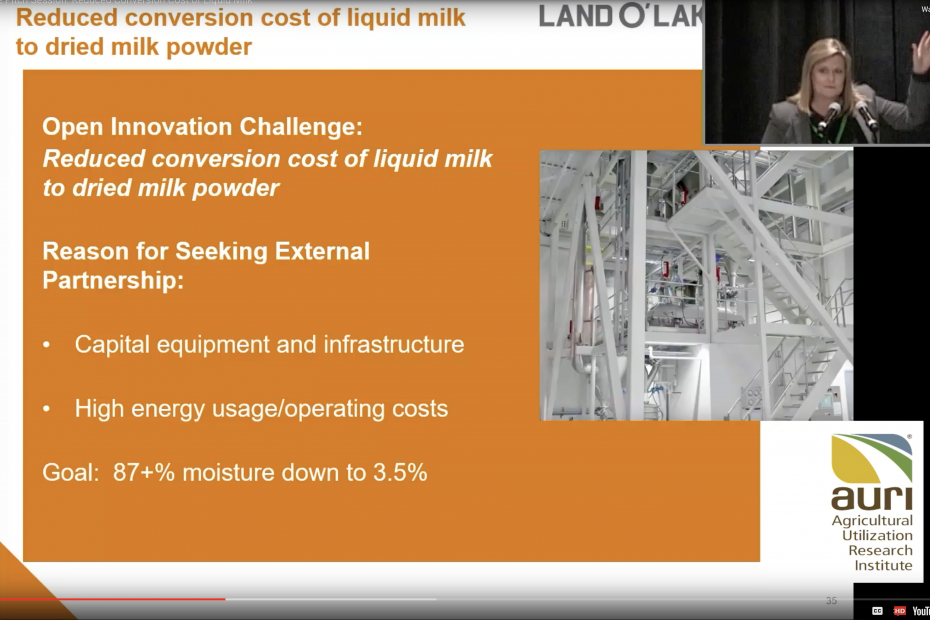

Reduced Conversion Cost of Liquid Milk

About Land O’Lakes: Land O’Lakes, Inc., one of America’s premier agribusiness and food companies, is a member-owned cooperative with industry-leading operations that span the spectrum from agricultural production to consumer foods. With 2018 annual sales of $15 billion, Land O’Lakes is one of the nation’s largest cooperatives, ranking 216 on the Fortune 500. Building on a legacy of more than 97 years of operation, Land O’Lakes today operates some… Continue Reading Reduced Conversion Cost of Liquid Milk