Fergus Falls, Minn. — When business gets tough, creativity is key. Some west central Minnesota manufacturers are hoping they can unlock new markets with bioproducts.

Harold Stanislawski, Fergus Falls Economic Improvement Commission executive director, is spearheading an effort by area manufacturers to produce more bioproducts. Some have excess capacity and are interested in renewable products, he says. One company is considering replacing some of its manufactured components with bioplastics.

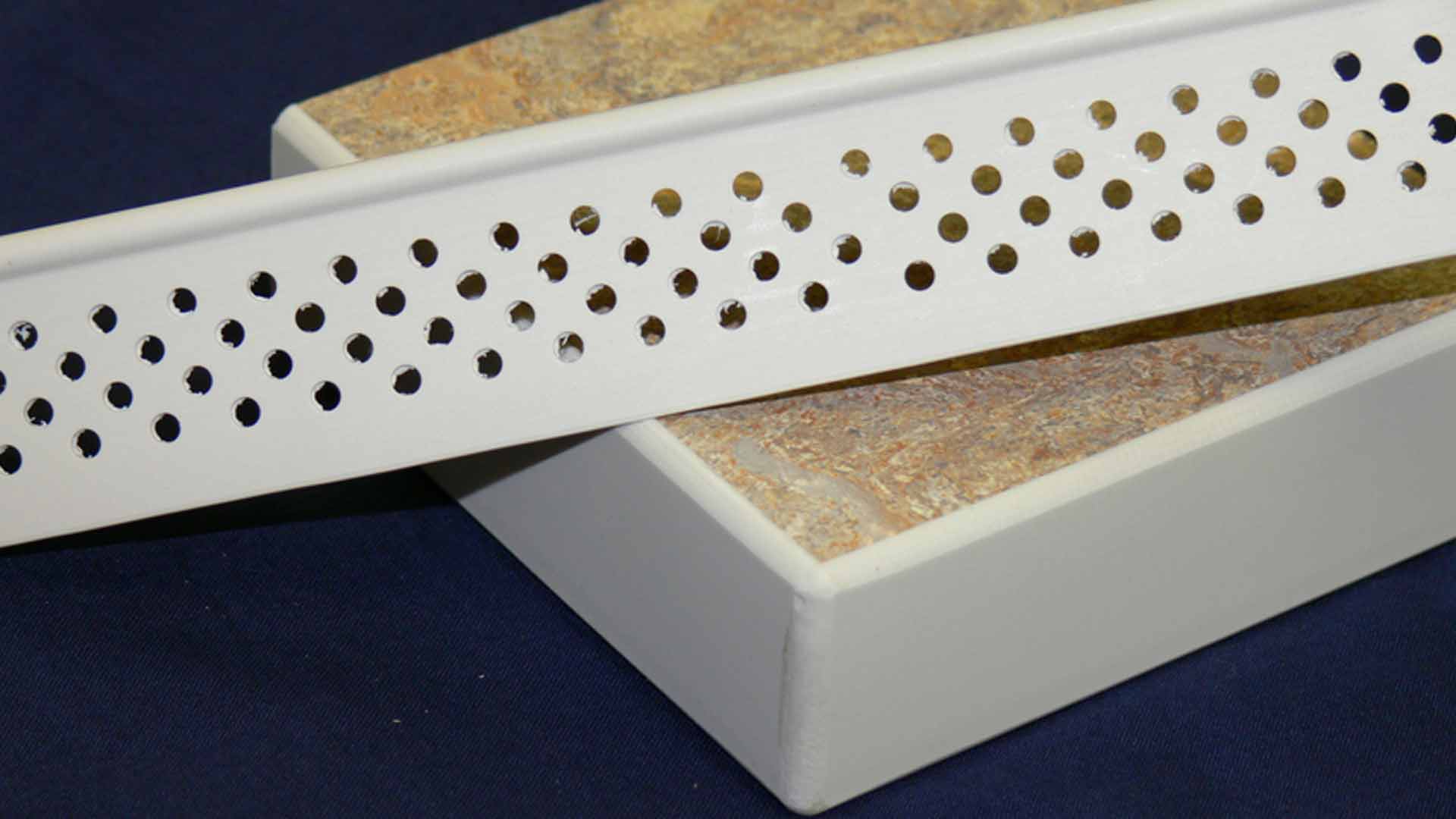

Typically made from soybean oil, corn starch or other ag-based renewable sources, bioplastic films, foams and rigid products could offer a ‘greener’ alternative with good market potential.

“A report from the Bio Business Alliance predicted that the renewable materials market was likely to grow,” Stanislawski says. “We looked at our assets to see if we have the capacity to be a player. We’ve identified several products made in our region that could be manufactured here using bioproducts.”

The west central region includes manufacturers of injection and rotational molded parts and sheet fabricators. “If renewable ingredients can meet their specifications, the market could be endless.”

AURI and the Minnesota Soybean Growers are sponsoring a market evaluation to determine what manufactured items or components made in the region could be converted to bioproducts and if it would be economical to make the switch.

Some bioproducts may need further scientific development to make sure they meet they meet the same specifications as traditional products. And cost could be a factor. Manufacturers aren’t likely to switch to a bioproduct that isn’t cost competitive. Results of the market study should be available in early summer.

“A lot of effort in bioproducts began with convincing county governments to buy them,” says Michael Sparby, AURI project director. “Getting bioproducts in manufacturing is the next logical step. It could give those manufacturers access to all kinds of new markets.”