–by Jonathan Eisenthal

photos by Rolf Hagberg

For more than a decade, AURI has recognized those businesses and small entrepreneurs who have excelled in innovation with its Ag Innovator of the Year Award. To look down the roll of honorees is to see inspiration and invention. Often these businesses take something that’s waste, or a product that’s undervalued, and transform it into something of great value and a sought-after product that generates sales and jobs. There is also the willingness to take risks—one award winner is no longer in business, and another never saw its project come to full fruition. But this spirit of entrepreneurship, and the risk-taking that goes with it, is an important part of creating an innovative culture.

2002- Pet Care Systems

Swheat Scoop, a renewably-sourced cat litter, was initially made by Pet Care Systems—now part of Farmers Union Industries.

“Our product is all natural, because it’s 100 percent wheat,” says Tom Moses, director of operations for Pet Care Systems, located in Detroit Lakes, Minnesota. “The natural side of the market is growing, and we’re positioned to take advantage of it.”

“AURI and their laboratories have been instrumental in improving the cost factors of the product,” explains Farmers Union Industries’ Chuck Neece. “They have worked on the processes that impact the efficacy of the product, tightening down quality control specs, so the product became more consistent for the consumer.”

2003- Mississippi Topsoils

What’s better than turning a sow’s ear into a silk purse? How about turning chicken processing plant waste into rich garden soil?

Mississippi Topsoils, located in Cold Spring, Minnesota, takes the protein-filled waste—a substance called secondary activated biosolids—from GNP Company, makers of Gold’n Plump Chicken, and turns it into a consistent, high-performing soil amendment marketed under the trade name “Soil Essentials.”

“The innovation in our approach comes in the use of a non-traditional method of composting, called an in-vessel containerized compost system,” says Brad Matuska, who founded the company with Math Miller. Each year, Mississippi Topsoils makes 3,000 cubic yards of Soil Essentials.

“The biosolids proteins from the chicken plant are of an extremely high quality,” Matuska says. “To take concentrated centers of organic waste materials and make it into a value-added product just makes a lot of sense.”

2004- Minnesota Soybean Processors

The farmers who formed the board of Minnesota Soybean Processors (MnSP) in Brewster in 1999 immediately joined an effort to convince the Minnesota legislature to support a new, greener form of fuel called biodiesel. It’s now a 63-million gallon a year industry in the state.

MnSP is a cooperative owned by 2,400 farmer-members. It has the capacity to crush more than 100,000 bushels of soybeans and produce 100,000 gallons of biodiesel each day.

In addition to AURI’s initial work with MnSP on biodiesel, AURI recently performed a feasibility study looking at a potential glycerin refinery for the co-op. Currently the MnSP sells its crude glycerin, a byproduct of biodiesel production, as an animal feed additive, or ships it to refineries in Chicago to process it for use in dozens of products.

2005- SoyMor

In 2005, SoyMor opened as the nation’s largest biodiesel manufacturing facility and the second to be built in Minnesota. The refinery has the capability to produce 30 million gallons of biodiesel per year from soybean oil, processing 3,150 gallons per day from 1,700 acres worth of soybeans — for an annual total of about 18 million bushels of soybeans.

The company was idled in 2008, but was purchased in 2011 by Renewable Energy Group, the nation’s largest biodiesel producer, resulting in 20 new jobs at facilities in Albert Lea, Minnesota. In October 2012 the company announced that it would embark on a $20 million dollar upgrade to the Albert Lea plant to accommodate multiple feedstock sources to produce biodiesel. That upgrade was completed in August 2013. Today the southern Minnesota plant continues to produce biodiesel for customers in Minnesota and also ships it to other markets in the US.

2006- FUMPA BioFuels

FUMPA BioFuels (part of Farmers Union Industries) was one of the pioneers of Minnesota’s biodiesel industry. Organizers began the process of setting up the plant and getting all the necessary certifications in order to help launch Minnesota’s 2 percent biodiesel mandate in 2005.

“The Minnesota Legislature had passed a 2 percent biodiesel requirement for all the diesel supply in Minnesota, but, in order for the requirement to kick in, there had to be a certain level of in-state production,” recalls Chuck Neece, the director of regulatory compliance for Farmers Union Industries. “Our plant was first, followed by two others.”

The biodiesel production part of the company wrapped up in 2010, but Farmers Union Industries (FUI) continues to diversify and prosper and has brought 350 jobs to Minnesota communities including Detroit Lakes, St. Cloud, Redwood Falls and Long Prairie.

2007- USA Solutions

“I was in the hog business for 25 years before launching USA Solutions,” remembers Darryl Metcalfe. “No matter how hard you tried you couldn’t get the rubber mats clean enough, and it caused health issues. I was working with the veterinarians one day, and they commented that the industry could really use a disposable mat to start with a fresh, clean one each time.

I just ran with the idea.”

Metcalfe and and his business partner Tony Schmitt designed a mat made from pressed corn stalks and wood products for use in farrowing barns, to replace the rubber mats, explains Metcalfe. “It’s designed to be broken into small pieces and fed back to gilts (female pigs prior to breeding and farrowing).”

The mats are made in Minnesota and Wisconsin and sold across the US and Canada. “Without AURI we probably would not exist,” says Metcalfe of AURI’s assistance.

2008- Northern Excellence Seed

Grass grows well in northwestern Minnesota. Being a turf seed producer like Northern Excellence Seed still means being choosy, though. It rejects about 20 percent of the seeds coming through its plant for conditioning.

Instead of treating this biomass as waste, Northern Excellence became excited by the promise of biomass gasification as a form of electrical generation. For its engagement in the development of this potentially important source of energy for rural Minnesota, AURI recognized Northern Excellence Seed with its Ag Innovator Award.

“This was a cutting-edge thing, and we put a lot of time and effort out there,” explains Brent Benike, the general manager of Northern Excellence Seed, who is both proud of that effort, and disappointed by the fact that the project never came to full fruition because other partners in the process stepped away.

Despite the disappointment, Northern Excellence remains strong in its forte: perennial rye grass, timothy and other turf seeds for lawns, roadside mixes, golf courses and

sod contractors.

2009- Alternative Energy Solutions

Diversification is clearly a deeply held value at the Kreidermacher Farm in Altura, Minnesota. The farm is home to a heritage hog operation, a greenhouse/nursery retail company and a biomass energy pellet manufacturer.

AURI recognized the pellet business, Alternative Energy Solutions, for being a pioneer in renewable home and commercial heating. Owned by siblings Eric, Paul and Maria Kreidermacher, the company manufactures fuel pellets from a combination of native grasses, wood and agriculture residues. The Kriedermachers also serve as dealers for biomass-capable boiler heating systems.

“Being a greenhouse grower in a northern climate means heat is one of our main expenses,” explains Eric Kriedermacher. By using the biomass pellets to heat their 65,000 square-foot greenhouse, Kreidermacher estimates they save between 50-60,000 gallons of propane. AURI worked with the Kreidermachers to develop the dies and die-specs needed to produce the fuel pellets and to configure the milling system.

2010- Suntava

Twin Cities-based Suntava regards its proprietary hybrids of purple corn as a treasure trove of healthful food ingredients, from a natural red colorant, to milled components for everything from snack bars to cereals. The company also has plans to announce a groundbreaking neutraceutical.

“The key ingredient in our purple corn is anthocyanin, which is both a natural ingredient and an antioxidant, with twice the antioxidant capacity of blueberries,” says Bill Petrich, CEO of Suntava. “Our purple corn is traditionally bred, not genetically modified. We have meticulously hand-bred our corn to get it to grow in the northern tier of the Corn Belt, and we continue to make improvements each year on our hybrids, each geared to different uses.”

Another recent addition to Suntava’s product list is nectar, a slightly sweet extract that can be used as a binding agent for snack bars, or as an ingredient in jellies and jams. Beer lovers fear not—one beer based on Suntava’s purple corn extract has launched and another will offer its brew by the end of the year.

2011- North American Fertilizer

FibroMinn burns about 700,000 tons of poultry litter collected from local farmers to produce 55 megawatts of power. The ash from the plant travels a 500-foot conveyer over to North American Fertilizer. Once there, North American Fertilizer takes the ash—which already contains a rich, well-balanced package of macro and micro nutrients—and processes it into fertilizer. It is the only operation of its kind in the United States, and only the second in

the world.

While North American Fertilizer employs just four people to run its operation, “there’s a trickle-down effect, in that the product goes out to dealers and supports lots of folks involved in the fertilizer and input business,” says Steve Miller, the general manager of the plant. CEO Randy Tersteeg started up the business seven years ago.

“What keeps North American Fertilizer vital is that we continually look for value-added markets—new uses for this package of nutrients,” explains Miller. “In that way we can grow our revenue for it.”

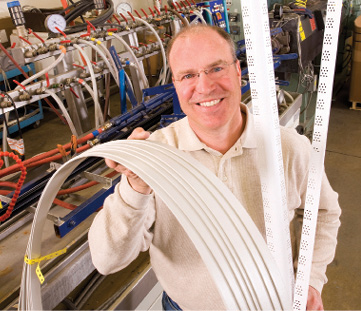

2012- Bio-Plastic Solutions

After years of development, this Blooming Prairie, Minnesota-based custom plastic extruder is now commercializing its products for the building and trades, and medical industries.

“Over the past 13 years we have been working with various organizations, suppliers and partners, to develop bioproducts from durable bioresins,” said Gary Noble, founder and CEO/president of Bio-Plastic Solutions. Bio-Plastic Solutions, which employs 13 people, takes raw material derived from corn, called Polylactic Acid, or PLA.

“We buy the raw material from NatureWorks, then we alter it and compound it to the specs we need for the performance we are after,” said Noble. “AURI is helping us to perfect our polymer blend. We’re also working with soybean-based polymers, and we’re branching out to organic fibers like straw and inorganic material such as glass or crushed rock.”

2013- Protein Resources, LLC

Soybean meal, while an excellent animal feed, still can’t be fed to a whole range of animals as soluble sugars in soybean meal are very disruptive to the digestive tract of baby pigs and carnivorous fish, in particular. That’s where Protein Resources, LLC, saw an opportunity to innovate and provide a feed ingredient that the market has been waiting for.

“We felt that the market was looking for a soy-based, high-protein feed supplement that could be used in a variety of applications such as baby pig diets, poultry, aquaculture, and possibly several other formulations,” says John Pollock, president of Protein Resources, LLC.

Nutrivance, the brand name of the product, is headquartered in Marshall, Minnesota.

2014- EarthClean Corporation

The EarthClean Corporation is being honored in 2014 for their work in creating an environmentally friendly fire suppressant using corn and soybeans.

The company creates TetraKO, a biodegradable water enhancer that changes plain water into an adhering gel that knocks down fires faster than water or foam—without harming the environment or wildlife. TetraKO also increases firefighter safety and decreases firefighting costs.

Watch for more about EarthClean in a future edition of Ag Innovation News!