by Dan Lemke

Americans have access to an abundant and safe food supply thanks to the agriculture industry’s accomplishments in producing and distributing thousands of food items. But, as good as the United States is at producing food, Americans are equally guilty of wasting it.

The U.S. Department of Agriculture (USDA) estimates that 30 to 40 percent of food in the United States goes to waste. Much of that loss occurs at the consumer level. Food spoils in refrigerators, there are mishandling issues, or consumers mistakenly throw out food because they misinterpret expiration labels.

In 2015, the USDA joined with the United States Environmental Protection Agency (EPA) to set a goal for cutting the nation’s food waste by 50 percent by the year 2030. National and state programs are in place to help educate consumers about food loss.

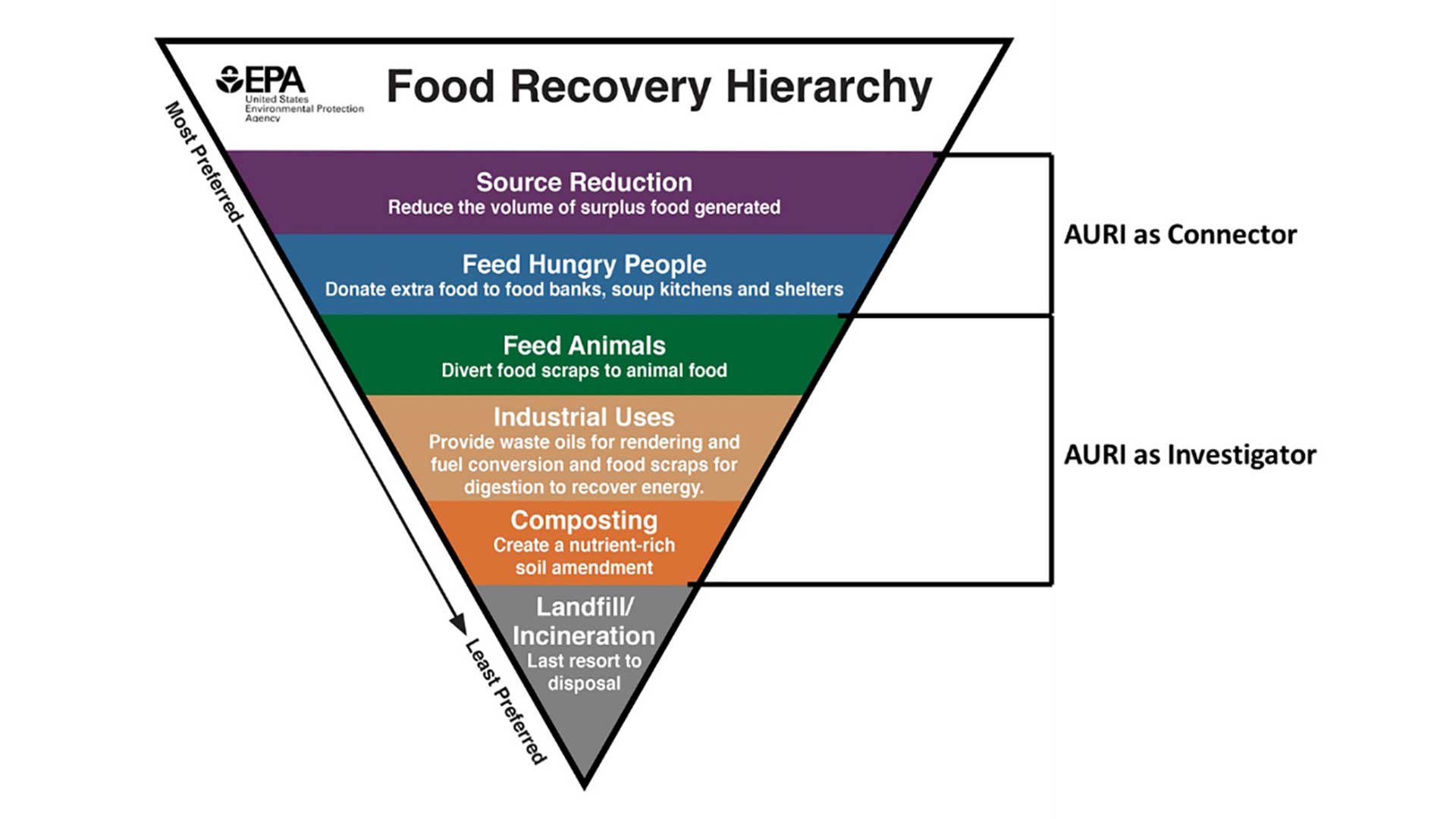

The EPA developed a Food Recovery Hierarchy, which prioritizes actions organizations can take to prevent and divert wasted food. Each tier of the hierarchy focuses on different management strategies for dealing with wasted food. The top levels of the hierarchy are the most impactful ways to prevent and divert wasted food because they create the most benefits for the environment, society, and the economy. The hierarchy places higher value on preventing food waste and loss or on repurposing those products for food use than on diverting the waste materials to animal feed or energy generation.

While consumer actions contribute heavily, food loss and waste also occur at each level of the value chain from production to commodity processing to distribution channels and retail settings.

AURI Fit

AURI has long focused on utilizing coproducts from agricultural processing to generate value, often for animal feed, fertilizers or energy. The organization is placing increased emphasis on identifying and catalyzing opportunities presented by food waste.

Last fall, AURI convened a food loss and waste thought leader’s roundtable. The group included some of the state’s largest and most well-known food companies and retailers, as well as government and industry partners. AURI also developed an Ag Innovation Partnership project with food loss expert Claire Sand of Packaging Technology and Research to identify opportunities to sustainably reduce food loss and waste in food processing and explore new uses for it.

“We wanted to identify some of the lowest hanging fruit in processing where food waste is occurring,” says Alan Doering, AURI senior scientist for coproducts. “Where can we step in to add value or to prevent food processing waste from occurring.”

With Minnesota being home to a vibrant food production and processing sector, AURI and Sand teamed up to review hundreds of food production and processing possibilities. The team narrowed the project to demonstrate opportunities in five areas that could reduce an estimated 1.1 billion pounds of waste. Those areas include canning products, apple processing, small cheese processing and unsalable milk and cheese.

“In terms of a company looking at food waste and wondering how they can build the business case to reduce it or repurpose it, that’s what we really focused on,” Sand says. “We looked at six Minnesota products where food waste was an issue and where there was sufficient volume.”

Although a significant amount of food waste occurs on the consumer level, altering consumer behavior is not part of AURI’s mission.

“We wanted to capture, identify and catalyze activity in food waste reduction and upcycling opportunities somewhere between the farmer and the retailer,” adds AURI Project Development Director for Food Jason Robinson.

Waste Opportunities

Minnesota has a sizable apple industry, growing apples both for consumption and cider production. Sand’s research showed cideries have as much as 77 percent waste. One cause for loss is molding apples, which produces patulin and makes apples unsuitable for cider production. However, fermenting apples into an alcoholic hard cider destroys the patulin. Vision sorting could help divert the bad apples, improving the cider-making process, reducing apple waste and potentially adding an additional revenue stream or entrepreneurial opportunity.

Canning crops like kidney beans generate waste at the state’s canneries because of broken pieces and solids from wastewater. Canneries pay substantial amounts of money for wastewater treatments. Screening the broken pieces and ultrafiltration of wastewater could generate opportunities to reuse bean pieces, save companies money and reduce environmental impacts.

Unsalable cheese and milk generate waste at the retail level. Approximately 22 percent of all cheese and 25 percent of milk at grocery stores goes out of date.

“Once it ages out at grocer, the producing company is responsible for some sort of usage or destruction of that product once the grocer returns it,” Robinson says.

It’s possible to reprocess those dairy products into feed, use them for energy generation or further processing to make cheese powder, lactose and monosaccharides for human consumption. However, removing the milk or cheese from its packaging does present a challenge for reuse.

Waste and loss at small cheese processors can exceed 90 percent, primarily because of residual whey from the milk. Whey is mostly water, but the remaining nutrients are capturable at small-scale cheese producers to make whey cream, cheese sauce, soluble cocoa powder products, demineralized whey for people with lactose intolerance and more.

“Big processors can do things with waste, like produce dairy protein isolates, but for the small processor, they’re going to have to deal with disposal,” Sand says. “Is there something small cheese businesses can do to still get some money out of this and decrease environmental cost?”

Sand says the study focused on six areas of production and processing, but she says this was to demonstrate that there are opportunities in many production areas.

“For each industry, the point of intervention is in different places,” Doering says. “The point where impact can be made on food waste is at different levels. Some is at the consumer level, some is at the farm, some is at the manufacturer, some is at retail.”

Business Decision

The possibilities for reducing food loss and waste are vast. However, for any company to make a change or for someone to pursue an entrepreneurial opportunity, it must make financial sense.

“To create an opportunity for a processor or an entrepreneur to step in, you really needed to create that business case,” Sand explains. “When you show a business that they’re throwing out money or you can save them money, they’re willing to listen.”

“The reason we look at how you prevent waste from occurring or why you want to add value through new product creation is because you already have investments and input costs into this material,” Doering says. “AURI is looking at a path to how we can continue to add value to waste before it ends up in the landfill.”

Robinson, who spent nearly two decades in the packaged food industry, says food companies want to do what they can to reduce costs, but they also recognize that consumer demands are changing, and sustainability is becoming more of a factor in purchasing decisions.

“Millennials and subsequent generations have access to more information than any generation prior and they tend to be more influenced by socioeconomic and environmental factors. They tend to focus purchase decisions not only on the impact to their personal wellbeing, but on the impact that purchasing decision might have on the world,” Robinson contends. “They want to hear more about global responsibility from companies.”

Path Forward

AURI and partners will share the results of the food loss and waste project widely with stakeholders and others across the state who have interest in pursuing an opportunity to turn waste into gain.

“The goal is to make sure that groups are aware of these opportunities and they can understand that some level of activity against food loss and waste might have a benefit to a consumer, industry partner or in improvements to their supply chain, so they don’t see a loss,” Robinson says.

“There’s a lot of momentum around food waste,” says Jen Wagner-Lahr, AURI senior director of innovation and commercialization. “The agriculture and food industry in general does a great job of not wasting a lot of products, but there still is waste. The greatest amount of waste happens at the consumer level—that is a nut for someone else to crack—but there’s certainly places where AURI can assist in terms of finding new uses or adding value to low value products.”

Wagner-Lahr says AURI will maximize the channels through which the report is available. She says in addition to posting the report online, AURI will conduct a webinar to share the information. AURI will also reconvene the food loss and waste thought leader’s roundtable to examine if other areas of food loss and waste need further examination.

In addition to generating information that could lead to value-added opportunities, Robinson says the effort reiterates that AURI has a valuable role in the food loss and waste space.

“I think of AURI as a connector at the highest level,” Robinson says. “We can help connect the dots in terms of prevention or reuse of wasted food and help put it back into a value chain.”

Information on the food loss and waste project is available at www.auri.org.

Coproduct Focus Area

Nearly every agricultural processor generates waste or coproducts. The AURI Coproducts Team works to create new uses for these byproducts, from developing the new equine feed mix featured in the cover story to helping AURI clients transform ag waste into products such as cooking oil, fertilizer and fuel. The result can create significant new revenue streams for Minnesotans.

Have an idea to repurpose food waste? Reach out to the Coproducts Team at www.auri.org/coproducts-team/.

Mining New Opportunities

AURI takes a proactive approach to uncovering value-added opportunities. In addition to supporting existing businesses and entrepreneurs with product development and process improvement assistance, AURI works with stakeholders and other partners find emerging opportunities through programs like the Agricultural Innovation Partnership (AIP) program.

The AIP catalyzes innovation, generates new ideas and supports collaborative partnerships while directing research and technology transfer opportunities that add value to Minnesota’s agricultural products or improve efficiencies in their processing.

“The AIP program really creates an avenue to be more collaborative and to seek new partnerships with groups that we haven’t necessarily worked with before or working on new things that really matter to our stakeholders,” says Jen Wagner-Lahr, AURI senior director of innovation and commercialization.

Every two years, AURI conducts a stakeholder analysis, meeting with dozens of groups and organizations to get feedback on what they would like AURI to focus on in the months ahead. The effort also helps AURI staff learn more about barriers and challenges faced by industry partners. AURI funds public domain research to help identify and address those concerns.

Work and research done as part of the AIP program focuses on AURI’s four priority areas, including biobased products, coproduct utilization, renewable energy and food. Deliverables include applied research studies and guides or tools to further the utilization and value of commodities and agricultural products. Previous project examples include a food shelf life guide and the recent food loss and waste evaluation.

Wagner-Lahr says a request for proposals (RFP) will be coming out later this summer.

“We will be looking for proposals that further value-added agriculture in Minnesota,” Wagner-Lahr says.

AURI will disseminate Information about the RFP process through its communication channels including social media, an E-newsletter and the AURI website.

Information generated through the AIP program is public domain and shared to help entrepreneurs, businesses and agricultural processors explore opportunities and technologies in the areas of biobased products, food, renewable energy and coproducts.

Complete program criteria, information on how to submit a proposal, and AIP program guidelines are all available at www.auri.org.