–By Liz Morrison

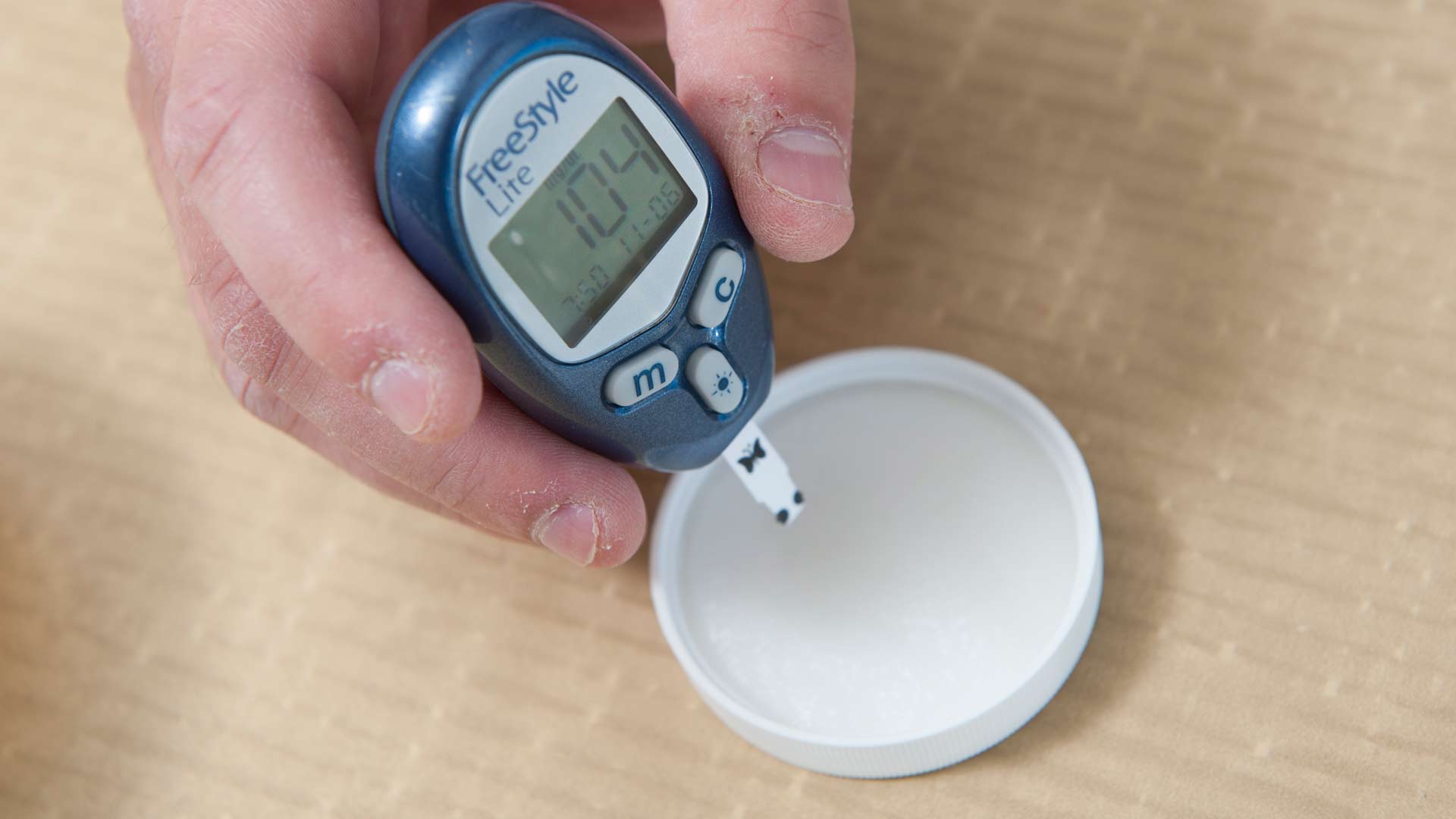

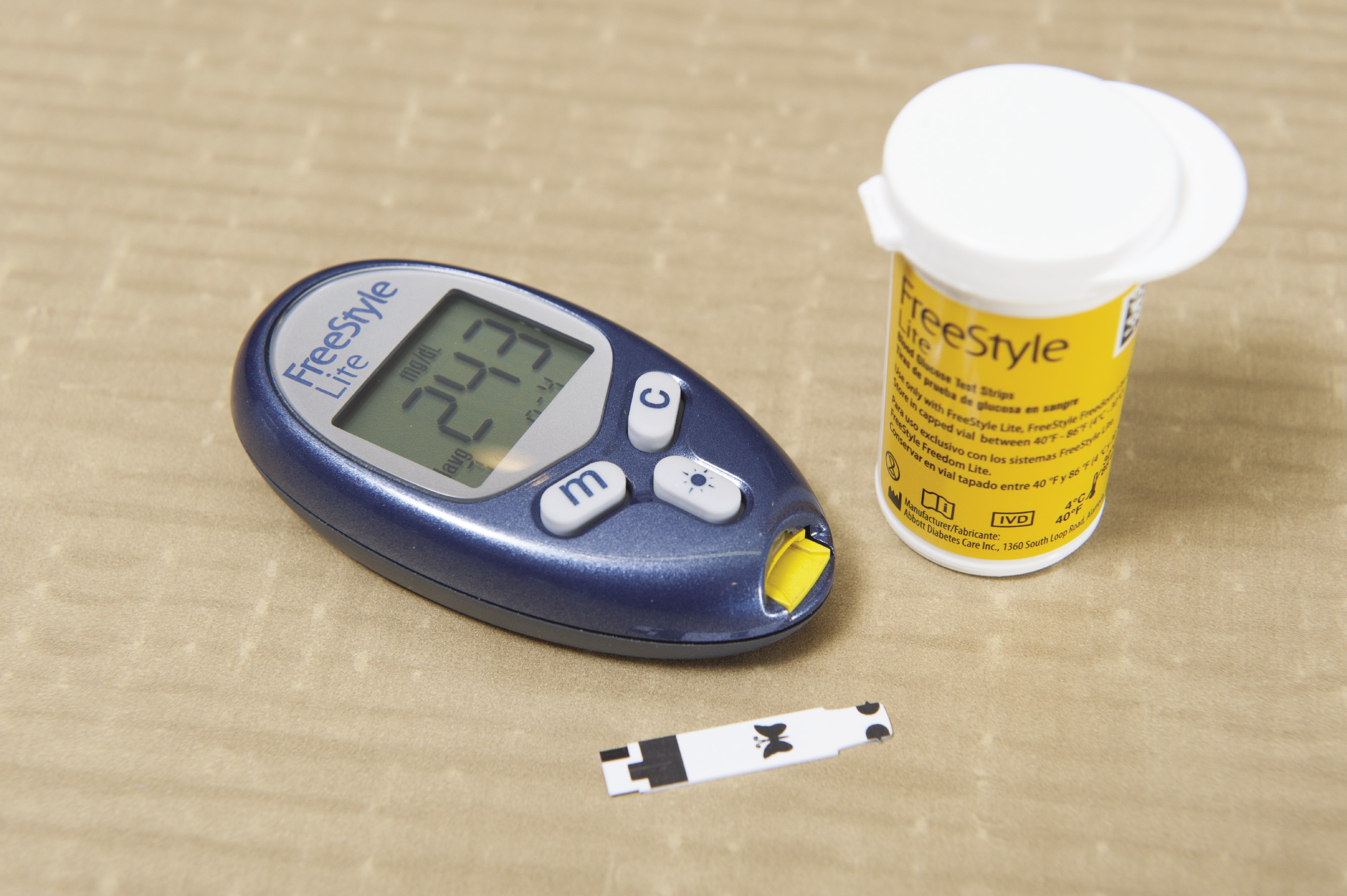

A cheap, reliable test for monitoring blood sugar in diabetics is being put to a new use — measuring milk sugar.

Research sponsored in part by AURI has made it practical for dairy processors to use blood glucose meters to test the lactose content of milk products. Lactose, a type of sugar, affects dairy food characteristics and quality. The new rapid test replaces a slow, expensive lab test, saving processors significant time, money and training.

“Anything we can do to help milk processors improve profitability is an advantage for agriculture,” says Jen Wagner-Lahr, AURI senior director of innovation and commercialization. Dairy products are Minnesota’s fourth largest agricultural commodity. And many of Minnesota’s 39 dairy processing plants are farmer-owned, Wagner-Lahr adds.

The rapid lactose test was developed at the Midwest Dairy Foods Research Center at South Dakota State University in Brookings. The Research Center, supported by checkoff dollars, is a consortium of food scientists from Minnesota, South Dakota, Iowa, Nebraska, Missouri and Kansas. The Center’s industry-focused research program is driven by the real-world needs of milk processors, Wagner-Lahr says.

Dairy processors routinely test for lactose, a major component of milk. Accurate lactose measurement is important in the manufacture of cheese and whey products, as well as lactose-free products, says dairy scientist and Center Director Lloyd Metzger, who led the research. The industry has been using complex lab tests that require skilled technicians and expensive instruments. “The dairy industry wanted a simple, quick and cost-effective method that could be done at the processing level, rather than in the lab.”

“Getting applied research and new technology like this into the hands of processors is critical to a strong future for the dairy industry,” explains Mary Wilcox, Midwest Dairy’s vice president for business development-manufacturing and research.. “We’re excited to give processors a reliable, faster and more affordable option for this critical testing.”

Tech transfer

Blood glucose meters for diabetics — developed after decades of extensive research and clinical trials — are inexpensive and reliable. They are also user friendly, quick, and need only a small sample. Metzger reasoned that a device for measuring sugar in blood — a very complex fluid — could also measure sugar in milk.

The dairy industry has borrowed other tools from the medical sector, Metzger says, such as the membrane filters used to separate and concentrate milk proteins. “It’s a matter of adapting the technology for use in the dairy industry.”

The dairy industry has borrowed other tools from the medical sector, Metzger says, such as the membrane filters used to separate and concentrate milk proteins. “It’s a matter of adapting the technology for use in the dairy industry.”

In a series of trials, Metzger and his colleagues developed a simple enzymatic process to convert milk lactose into glucose. Then they used a ReliOn Ultima blood glucose meter and test strips from Wal-Mart to measure the glucose concentration in the sample. Metzger also developed a standardized chart to convert the glucose reading back to lactose.

The new method — validated in subsequent trials — is simple and requires minimal training to perform, Metzger says. It costs less than $0.50 per sample, and the results are available in a few minutes.

That’s a huge savings in time and money over the standard lab tests, says Suvash Kafley, research director of Eden Prairie-based Milk Specialties Global, which makes milk protein and  whey-based food ingredients. Milk Specialties operates dairy processing facilities in Minnesota, Wisconsin and other states.

whey-based food ingredients. Milk Specialties operates dairy processing facilities in Minnesota, Wisconsin and other states.

The company’s dairy plants generally don’t have on-site labs, so they send samples to an outside lab, then wait 7 to 14 days for the results. The cost can run as high as $140 per sample, he says. Even processors with an in-house lab spend a significant amount on lactose tests —about $15 per sample, not counting the cost of the lab and instruments —and wait several hours for results, Metzger says. Because of this time delay, those test results can’t be used to monitor or adjust the current batch of dairy products, a big disadvantage for process control.

Milk Specialties is now testing the rapid glucose method in some of its plants, and eventually expects to use it in all its facilities. The new test has the capacity to improve both product quality and processing efficiency, Kafley says.

“We see a lot potential, not just for our company, but for the industry as a whole.”

Research aids Minnesota’s dairy manufacturing

AURI has worked with the Midwest Dairy Foods Research Center on a variety of research to improve the safety, quality and profitability of processed dairy products, including:

- Low-salt cheese for school lunch programs.

- Technology to pasteurize whey beverages.

- Manufacturing techniques for making extruded puffs and crisps from high-calcium nonfat dry milk.

- New ways to clean and maintain the membrane filters used in cheese processing.

- Natural antifungal substances to deter mold growth in shredded cheese.

Minnesota’s dairy industry at a glance

Sources: Minnesota Agricultural Statistics Service, Midwest Dairy Association

Minnesota, the seventh largest dairy producing state, has 3,952 licensed dairy herds and 39 dairy processing plants. The state’s dairy sector annually produces:

460 million pounds of food-grade dry whey

670 million pounds of ice cream

More than 1 billion gallons of milk

AURI and Midwest Dairy Foods Research Center

Idea to reality:

Dairy processors needed a faster, cheaper way to determine the lactose content of milk.

AURI’s role:

AURI partnered with the Midwest Dairy Foods Research Center to develop a rapid lactose test using an inexpensive blood glucose meter.

Outcomes:

The new test procedure will save dairy manufacturers time and money and will improve product quality and processing efficiency. It is now being used in commercial plants.