–by Ashley Harguth

Slow melting ice cream

Slow melting ice cream

Researchers from the University of Edinburgh and the University of Dundee, both in the United Kingdom, discovered that a protein called BsIA can be used as an ingredient to keep everything combined in ice cream and result in slower melting. The typical ingredients in ice cream don’t want to mix together and an emulsifier needs to be added to prevent separation. When using BsIA instead of common ice cream emulsifiers, the ingredients are bound tightly together and the ice cream melts much more slowly. Emulsifiers are typically fatty elements, but since they’re being replaced with a protein, that means less fat and fewer calories for ice cream lovers.

October 2015 livescience.com

Bringing up biofuel

USDA scientists have advanced a process to produce bio-oil, a crude liquid from agricultural waste with a mobile reactor. Crude bio-oil is produced by pyrolysis—a process that chemically decomposes plant and other organic matter using very high heat. The modified technique, called “tail-gas reactive pyrolysis,” or TGRP, holds promise for improving the bio-oil that is ultimately processed into finished biofuels.

The raw biomass material includes non-food-grade plant matter procured from agricultural or household waste residue such as wood and switchgrass, and animal manures. Using these materials, bio-oils are produced at an accelerated rate using a new high-output mobile processing unit. Instead of shipping large amounts of agricultural waste to a refinery plant at high cost, the mobile reactor allows conversion of the biomass into energy-dense bio-oil right on the farm.

The goal of using TGRP on the farm is to yield a higher quality bio-oil that is more marketable to biofuel producers than bio-oil made from traditional pyrolysis methods. TGRP is an important step toward the ultimate goal of producing cleaner bio-oils that can be distilled at existing petroleum refineries.

January 2016 USDA-ARS

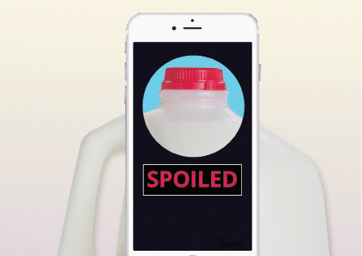

Smart covers for food

Smart covers for food

Accidentally drinking spoiled milk might become a thing of the past. Engineers from the University of California Berkeley and Taiwan’s National Chiao Tung University are developing technology that allows electrical components to be embedded in 3D-printed plastics. They have used this technology to create a smart milk carton cap, which monitors signs of spoilage. Once fitted, the container can be tipped upside-down to quickly test for changes in electrical signals that accompany high levels of bacteria. “This 3D-printing technology could eventually make electronic circuits cheap enough to be added to packaging to provide food safety alerts for consumers”, said Liwei Lin, a senior author on the paper describing the discovery. “You could imagine a scenario where you can use your cellphone to check the freshness of food while it’s still on store shelves.”

July 2015 Tech Radar

Wine grape flours

Wine grape flours

USDA-Agricultural Research Service chemist Wallace Yokoyama and colleagues are working to learn more about flours made from wine grape seeds. Along with potential health benefits, it would offer a new market for wine grape seeds that traditionally go to feed, composts or landfills.

Initial tests on hamsters have shown lower cholesterol levels and reduced weight gain. Research, now being conducted at Mayo Clinic, will determine whether the benefits will also occur in humans. Yokoyama is doing further research with rats to see if changes in the kind and amounts of bacteria in the gut are affected. Gut bacteria may play a role in controlling obesity or reducing risk of type 2 diabetes.

September 2015 USDA-ARS